Introduction to Flow Characteristics

Flow Characteristic describes the relationship between the valve coefficient (Cv) and the valve stroke. Each throttling valve has a flow characteristic. As a valve opens, the flow characteristic allows a certain amount of flow through the valve at a particular percentage of the stroke. Flow characteristic allows the valve to control the flow in a predictable manner, which is important when using a throttling valve.

Inherent and Installed Flow Characteristic

The flow rate through a throttling valve is not only affected by the flow characteristic of the valve, but also by the pressure drop across the valve. A valve’s flow characteristic acting within a system that allows a varying pressure drop can be much different or can vary significantly from the same flow characteristic in an application with a constant pressure drop.

When a valve is operating with a constant pressure drop without taking into account the effects of entire piping system, the flow characteristic is known as inherent flow characteristic.

When a valve is operating with a varying pressure drop taking into account the effects of entire piping system, the flow characteristic is known as installed flow characteristic.

Types of Flow Characteristics

The three most common types of flow characteristics are:

- Equal Percentage Flow Characteristic

- Linear Flow Characteristic

- Quick Open Flow Characteristic

The ideal curves for these three inherent flow characteristics are shown in the figure below.

Typical Inherent Flow Characteristic Curves

Equal Percentage Flow Characteristic

In Equal Percentage Flow Characteristic, the change in flow per unit of valve stroke is directly proportional to the flow occurring just before the change in valve stroke is made. With an inherent equal percentage flow characteristic, the flow rate is small at the beginning of the stroke and increase to a larger magnitude at the end of the stroke. This provide good, exact control of the closure element in the first half of the stroke, where control is harder to maintain because the closure element is more prone to the process forces. On the other hand this provides increased flow capacity in the second half of the stroke. An equal percentage flow characteristic results in improved range-ability, better repeat-ability and resolution for a particular valve.

The addition of the piping effects has a tendency to move the installed flow characteristic away from ideal equal percentage characteristic towards the inherent linear characteristic. This is usually the case when the process systems pressure drop is larger than the pressure drop across the valve.

Linear Flow Characteristic

In Linear Flow Characteristic, the change in flow per unit of valve stroke remains equal, regardless the position of valve. Linear flow characteristics are usually specified in those process systems where the majority of the pressure drop is taken through the valve. Linear flow characteristic provide better flow capacity throughout the entire stroke as opposed to equal percentage flow characteristic.

In Linear Flow Characteristic, the change in flow per unit of valve stroke remains equal, regardless the position of valve. Linear flow characteristics are usually specified in those process systems where the majority of the pressure drop is taken through the valve. Linear flow characteristic provide better flow capacity throughout the entire stroke as opposed to equal percentage flow characteristic.

The addition of the piping effects has a tendency to move the installed flow characteristic away from ideal linear flow characteristic towards the inherent quick open flow characteristic.

Quick Open Flow Characteristic

In Quick Open Flow Characteristic, maximum flow is produced immediately as the valve begins to open. Quick open characteristic provides large changes in flow for very small changes in lift. It usually has too high a valve gain for use in modulating or throttling control. So it is limited almost exclusively for on-off services.

In Quick Open Flow Characteristic, maximum flow is produced immediately as the valve begins to open. Quick open characteristic provides large changes in flow for very small changes in lift. It usually has too high a valve gain for use in modulating or throttling control. So it is limited almost exclusively for on-off services.

Because of the extreme nature of quick open flow characteristic, the addition of the piping effect does not have any effect making the inherent and installed characteristics similar.

Choosing the Correct Flow Characteristic

During selection of throttling valve, a choice must be made between linear and equal percentage characteristic. Two general rules foe choosing the valve:

- If most of the pressure drop is taken through the valve and the upstream pressure is constant, a linear characteristic will provide the best control. However such systems are rare. A linear characteristic is also recommended when a variable head flowmeter is installed in the system.

- If the piping and downstream equipment provide significant resistance to the system, the equal percentage characteristic should be chosen. This is usually the case with with most process systems today. The equal percentage characteristic is also used for applications of high pressure drops with low flows and low pressure drops with high flows.

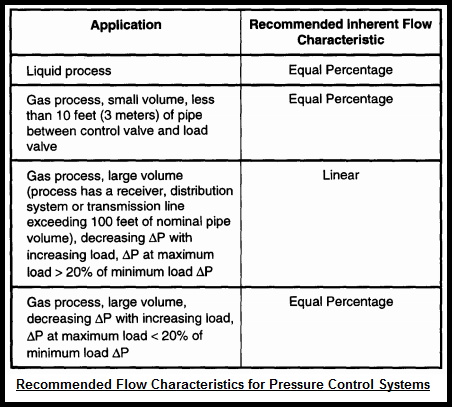

Below tables provide more specific recommendations depending on whether the system is for liquid level, pressure control, flow control or any other type of system.

a technical knowledge base for all the process piping professionals around the world…