Introduction to Flanges

Flanges are used when the piping joint needs dismantling. These are used mainly at equipment’s, valves and specialties. In certain pipelines where maintenance is a regular feature, breakout flanges are provided at definite intervals. A flanged joint is composed of three separate and independent although interrelated components; the flanges, the gaskets and the bolting. Special controls are required in the selection and application of all these elements to attain a leak-proof joint.

Classification of flanges is done in several alternate ways as follows;

Based On Pipe Attachment

Flanges can be classified based on the method of attachment to the piping as below;

-

Slip On Flange –

The Slip On type flanges are attached by two fillet welds, inside as well as outside the flange. The calculated strength from a Slip On flange under internal pressure is of the order of two-thirds that of Welding Neck flanges, and their life under fatigue is about one-third that of the latter. Normally, these flanges are of forged construction and are provided with hub. Sometimes, these flanges are fabricated from plates and are not provided with the hub.The disadvantage of the flange is that a combination of flange and elbow or flange and tee is not possible because named fittings have not a straight end that complete slid in the Slip On flange.

-

Socket Weld Flange –

The Socket weld flanges are attached by only one fillet weld, only on outside, and are not recommended for severe services. These are used for small-bore lines only. Their static strength is equal to Slip On flanges, but their fatigue strength is 50% greater than double-welded Slip On flanges. The thickness of connecting pipe should be specified for this type of flanges to ensure proper bore dimension.In socket weld flange, before welding, a space must be created between flange or fitting and pipe. ASME B31.1 Preparation for Welding (E) Socket Weld Assembly says:In assembly of the joint before welding, the pipe or tube shall be inserted into the socket to the maximum depth and then withdrawn approximately 1/16″ (1.6 mm) away from contact between the end of the pipe and the shoulder of the socket.The purpose for the bottoming clearance in a Socket Weld is usually to reduce the residual stress at the root of the weld that could occur during solidification of the weld metal. The image shows you the X measure for the expansion gap.The disadvantage of socket weld flange is right the gap, that must be made. By corrosive products, and mainly in stainless steel pipe systems, the crack between pipe and flange can give corrosion problems. In some processes this flange is also not allowed.

-

Screwed Flange –

The Screwed or Threaded flanges are used on pipe lines where welding cannot be carried out. A threaded flange or fitting is not suitable for a pipe system with thin wall thickness, because cutting thread on a pipe is not possible. Thus, thicker wall thickness must be chosen.ASME B31.3 Piping Guide says:

Where steel pipe is threaded and used for steam service above 250 psi or for water service above 100 psi with water temperatures above 220° F, the pipe shall be seamless and have a thickness at least equal to schedule 80 of ASME B36.10.Socket welding and threaded flanges are not recommended for service above 250°C and below -45 C.

-

Lap Joint Flange –

The Lap joint flanges are used with stub ends when piping is of a costly material. For example, in a stainless steel pipe system, a carbon steel flange can be applied, because flange will not come in contact with the product in the pipe. The stub ends will be butt-welded to the piping and the flanges are kept loose over the same. The inside radius of these flanges is chamfered to clear the stub end radius.These flanges are nearly identical to a Slip On flange with the exception of a radius at the intersection of the flange face and the bore to accommodate the flanged portion of the Stub End. Their pressure-holding ability is little, if any, better than that of Slip On flanges and the fatigue life for the assembly is only one tenth that of Weld Neck flanges. Thus this flange connections are applied in low-pressure and non critical applications.

-

Weld Neck Flange –

Welding Neck Flanges are easy to recognize as the long tapered hub, that goes gradually over to the wall thickness from a pipe or fitting. The long tapered hub provides an important reinforcement for use in several applications involving high pressure, sub-zero and / or elevated temperatures. The smooth transition from flange thickness to pipe or fitting wall thickness effected by the taper is extremely beneficial, under conditions of repeated bending, caused by line expansion or other variable forces.These flanges are bored to match the inside diameter of the mating pipe or fitting so there will be no restriction of product flow. This prevents turbulence at the joint and reduces erosion. They also provide excellent stress distribution through the tapered hub.The Weld neck flanges are attached by butt-welding to the pipes. These are used mainly for critical services where all the weld joints need radiographic inspection. While specifying these flanges, the thickness of the welding end also should be specified along with flange specification.

-

Blind Flange –

Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings.From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types.However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

-

Reducing Flange –

The Reducing flanges are used to connect between larger and smaller sizes without using a reducer. In case of reducing flanges, the thickness of the flange should be that of the higher diameter. These flanges normally come in blind, slip-on, threaded and weld neck flanges. They are available in all pressure classes and provide a good alternative to connecting two different sizes of pipe. This type of flange should not be used if an abrupt transition would create unwanted turbulence, such as at a pump.

-

Integral Flange –

Integral flanges are those, which are cast along with the nozzle neck or the vessel or pipe wall, butt-welded thereto, or attached by other forms of arc or gas welding of such a nature that the flange and the nozzle neck or vessel or pipe wall is considered to be the equivalent of an integral structure. In welded construction, the nozzle neck or the vessel or pipe wall is considered to act as a hub. Thickness of integrally cast flanges and welded on flanges differ in certain sizes.

Based On Facing

The flanges can also be classified based on the facings as below:

-

Raised Face Flange (RF) –

The Raised Face flange is the most common type used in process plant applications, and is easily to identify. It is referred to as a raised face because the gasket surfaces are raised above the bolting circle face. This face type allows the use of a wide combination of gasket designs, including flat ring sheet types and metallic composites such as spiral wound and double jacketed types. The purpose of a RF flange is to concentrate more pressure on a smaller gasket area and thereby increase the pressure containment capability of the joint. For 150# and 300# flanges, the raised face is of 1.6 mm (1/16 inch) and is included in the thickness specified. For higher rating, the flange thickness does not include the raised face thickness. The raised face thickness for higher rating is 6.4 mm (1/4 inch). The typical flange face finish for ASME B16.5 RF flanges is 125 to 250 µin Ra (3 to 6 µm Ra).

-

Flat Face Flange (FF) –

The Flat Face flange has a gasket surface in the same plane as the bolting circle face. Applications using flat face flanges are frequently those in which the mating flange or flanged fitting is made from a casting. Flat face flanges are never to be bolted to a raised face flange. ASME B31.1 says that when connecting flat face cast iron flanges to carbon steel flanges, the raised face on the carbon steel flange must be removed, and that a full face gasket is required. This is to keep the thin, brittle cast iron flange from being sprung into the gap caused by the raised face of the carbon steel flange.

-

Ring Type Joint (RTJ) –

The Ring Type Joint flanges are typically used in high pressure (Class 600 and higher rating) and/or high temperature services above 800°F (427°C). They have grooves cut into their faces which seats ring gaskets. The flanges seal when tightened bolts compress the gasket between the flanges into the grooves, deforming the gasket to make intimate contact inside the grooves, creating a metal to metal seal. An RTJ flange may have a raised face with a ring groove machined into it. This raised face does not serve as a part of the sealing means. For RTJ flanges that seal with ring gaskets, the raised faces of the connected and tightened flanges may contact each other. In this case the compressed gasket will not bear additional load beyond the bolt tension, vibration and movement cannot further crush the gasket and lessen the connecting tension.

Ring Type Joint gaskets are metallic sealing rings, suitable for high-pressure and high-temperature applications. Ring Type Joint gaskets are designed to seal by “initial line contact” or wedging action between the mating flange and the gasket. By applying pressure on the seal interface through bolt force, the “softer” metal of the gasket flows into the microfine structure of the harder flange material, and creating a very tight and efficient seal. Most applied type is style R ring that is manufactured in accordance with ASME B16.20 used with ASME B16.5 flanges, class 150 to 2500. Style “R” ring type joints are manufactured in both oval and octagonal configurations.

The octagonal cross section has a higher sealing efficiency than the oval and would be the preferred gasket. The sealing surfaces on the ring joint grooves must be smoothly finished to 63 microinches and be free of objectionable ridges, tool or chatter marks. They seal by an initial line contact or a wedging action as the compressible forces are applied. The hardness of the ring should always be less than the hardness of the flanges.

For more on Gaskets, check out: Introduction to Gaskets.

-

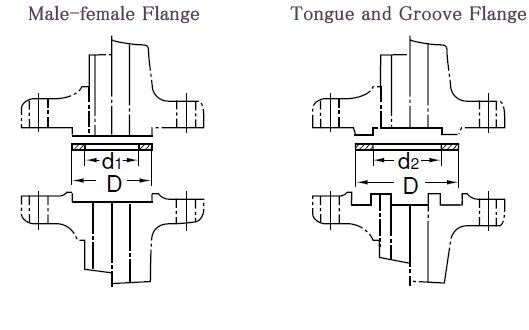

Tongue and Groove (T/G) –

One flange face has a raised ring (Tongue) machined onto the flange face while the mating flange has a matching depression (Groove) machined into it’s face. The Tongue and Groove faces of this flanges must be matched. Tongue-and-groove facings are standardized in both large and small types. They differ from male-and-female in that the inside diameters of the tongue-and-groove do not extend into the flange base, thus retaining the gasket on its inner and outer diameter. These are commonly found on pump covers and Valve Bonnets. Tongue-and-groove joints also have an advantage in that they are self-aligning and act as a reservoir for the adhesive. The scarf joint keeps the axis of loading in line with the joint and does not require a major machining operation.

-

Male and Female (M/F) –

With this type the flanges also must be matched. One flange face has an area that extends beyond the normal flange face (Male). The other flange or mating flange has a matching depression (Female) machined into it’s face. The female face is 3/16-inch deep, the male face is 1/4-inch high, and both are smooth finished. The outer diameter of the female face acts to locate and retain the gasket. Custom male and female facings are commonly found on the Heat Exchanger shell to channel and cover flanges. The female face and the male face are smooth finished. The outer diameter of the female face acts to locate and retain the gasket.

General flange faces such as the RTJ, T&G and the F&M shall never be bolted together. The reason for this is that the contact surfaces do not match and there is no gasket that has one type on one side and another type on the other side.

Based On Pressure-Temperature Rating

The flanges are also classified by the pressure temperature rating in ASME B 16.5 as below;

- 150#

- 300#

- 400#

- 600#

- 900#

- 1500#

- 2500#

Pressure temperature rating charts, in the standard ASME B 16.5, specify the nonshock working gauge pressure to which the flange can be subjected to at a particular temperature. Flanges can withstand different pressures at different temperatures. As temperature increases, the pressure rating of the flange decreases. The indicated pressure class of 150#, 300#, etc. are the basic ratings and the flanges can withstand higher pressures at lower temperatures. ASME B 16.5 indicates the allowable pressures for various materials of construction vis-a-vis the temperature. ASME B16.5 does not recommend the use of 150# flanges above 400 °F (200 °C). The Pressure Class or Rating for flanges will be given in pounds. Different names are used to indicate a Pressure Class. For example: 150 Lb or 150 Lbs or 150# or Class 150, all are means the same.

Based On Face Finish

There are two types of finishes done on to the facings.

-

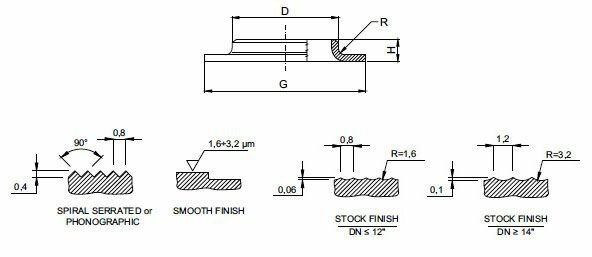

Stock Finish –

The most widely used of any flange surface finish, because practically, is suitable for all ordinary service conditions. Under compression, the soft face from a gasket will embed into this finish, which helps create a seal, and a high level of friction is generated between the mating surfaces. The finish for these flanges is generated by a 1.6 mm radius round-nosed tool at a feed rate of 0.8 mm per revolution up to 12 inch. For sizes 14 inch and larger, the finish is made with 3.2 mm round-nosed tool at a feed of 1.2 mm per revolution.

-

Smooth Finish Flange –

This finish shows no visually apparent tool markings. These finishes are typically utilized for gaskets with metal facings such as double jacketed, flat steel and corrugated metal. The smooth surfaces mate to create a seal and depend on the flatness of the opposing faces to effect a seal. This is typically achieved by having the gasket contact surface formed by a continuous (sometimes called phonographic) spiral groove generated by a 0.8 mm radius round-nosed tool at a feed rate of 0.3 mm per revolution with a depth of 0.05 mm. This will result in a roughness between Ra 3.2 and 6.3 micrometers (125 – 250 micro inch).

-

Serrated Finish –

This is also a continuous or phonographic spiral groove, but it differs from the stock finish in that the groove typically is generated using a 90-deg tool which creates a “V” geometry with 45° angled serration. The serrations provided on the facing could be concentric or spiral (phonographic). Concentric serrations are insisted for face finish when the fluid being carried has very low density and can find leakage path through the cavity. The serration is specified by the number, which is the Arithmetic Average Roughness Height (AARH). This is the arithmetic average of the absolute values of measured profile height deviations taken within the sampling length and measured from the graphical centre line.

The smooth finish flanges are specified when metallic gaskets are specified and serrated finish is provided when a non-metallic gasket is provided.

Based On Material Of Construction

The flanges are normally forged except in very few cases where they are fabricated from plates. When plates are used for fabrication, they should be of weldable quality. ASME B16.5 allows only reducing flanges and blind flanges to be fabricated from plate. The materials of construction normally used are as follows;

- ASTM A105 – Forged Carbon Steel

- ASTM A181 – Forged Carbon Steel for General Purpose

- ASTM A182 – Forged Alloy Steel and Stainless Steel

- ASTM A350 – Forged Alloy Steel for low temperature services

a technical knowledge base for all the process piping professionals around the world…