Introduction to the SAE / AISI Steel Numbering System

For an Introduction on types of Steel in Process Piping Industry, check out;

AISI – American Iron and Steel Institute

SAE – Society of Automotive Engineers

ASME – American Society of Mechanical Engineers

The early 1940’s witnessed the development of a coding system for the classification of different types of steels. Designers, heat treaters, draftsmen, and engineers were able to obtain specific information on the types of steel along with its grades. The coding system is known for its efficient classification of steels as it uses the standards from the American Iron and Steel Institute (A.I.S.I.) and the Society of Automotive Engineers (S.A.E.).

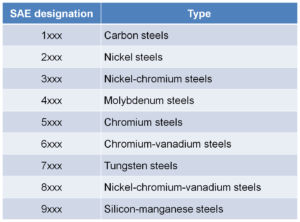

The SAE system uses a basic four-digit system to designate the chemical composition of carbon and alloy steels. The simplest system for designation of steel is schematically shown in Figure 1.

Figure 1 – Schematic Representation of AISI/SAE Steel Designation System

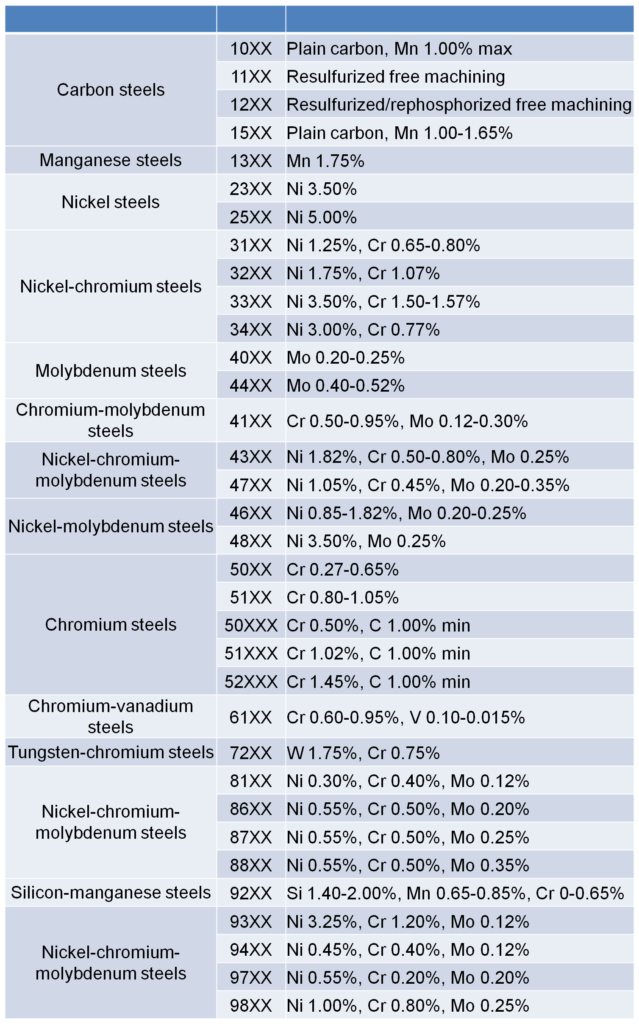

It is worth noting however, that there are also certain types of alloy steels that are designated by five digits (51XXX; 52XXX).

The first digit (1), of this designation indicates a carbon steel; i.e., carbon steels comprise 1xxx groups in the SAE-AISI system and are subdivided into four categories due to the variance in certain fundamental properties among them. Thus the plain carbon steels are comprised within the 10xx series (containing 1.00% Mn maximum); resulfurized carbon steels within the 11xx series; resulfurized and rephosphorized carbon steels within the 12xx series; and non-resulfurized high-manganeze (up-to 1.65%) carbon steels which are produced for applications requiring good machinability are comprised within the 15xx series.

The SAE-AISI system then classifies all other alloy steels using the same four digit index as follows: 2 – Nickel steels; 3 – Nickel-chromium steels; 4 – Molybdenum steels; 5 – Chromium steels; 6 – Chromium-vanadium steels; 7 – Tungsten-chromium steels; 9 – Silicon-manganese steels.

The second digit of the series indicates the concentration of the major element in percentiles (1 equals 1%). The last two digits of the series indicate the carbon concentration to 0.01%.

For Example :

- SAE 1018 indicates non-modified carbon steel containing 0.18% of carbon.

- SAE 5130 indicates a chromium steel alloy, containing 1% of chromium and 0.30% of carbon.

The last two digits are most important for welding because they indicate carbon in hundredths of a percent.

Table 1 shows the SAE/AISI steel Numbering designation system.

Table 1: The SAE/AISI steel numbering designation system

An additional letter is sometimes added between the second and third digits of the code groups such as 11L41, 12L14 or 50B40. Additional letters added between the second and third digits include B when boron is added (between 0.0005 and 0.003%) for enhanced hardenability, and L when lead is added (between 0.15 and 0.35%) for enhanced machinability. The prefix M is used to designate merchant quality steel (the least restrictive quality descriptor for hot-rolled steel bars used in noncritical parts of structures and machinery). The prefix E (electric-furnace steel) and the suffix H (hardenability requirements) are mainly applicable to alloy steels.

Additional Information

For many years, certain grades of carbon and alloy steels have been designated by a four-digit AISI/SAE numerical index system that identified the grades according to standard chemical compositions. Since the American Iron and Steel Institute (AISI) ceased writing material specifications, the relationship between AISI and grade designations has been discontinued. From point of edition of the 1995 Iron and Steel Society (ISS) Strip Steel Manual, the four-digit designations are referred to solely as SAE Designations.

a technical knowledge base for all the process piping professionals around the world…